Merry Christmas and Happy New Year!

For our holiday delivery timeframes, please click here.

Blog The Complete Buyer’s Guide to Tyvek Wristbands (Plain vs. Custom)

Tyvek wristbands are tear-resistant, water-resistant, single-use identification bands made from DuPont Tyvek (HDPE), ideal for low-cost, one-day access control and quick visual checks at events. Event organisers choose them for their unbeatable combination of affordability, durability, and ease of use across diverse event conditions.

These durable wristbands act as reliable guest identification. Whether you’re running a school fete or corporate function, knowing the difference between plain Tyvek bands and custom Tyvek bands can help you make smarter purchasing decisions.

Plain options offer speed and simplicity for last-minute events, whilst custom variants deliver branding opportunities and enhanced security features for professional gatherings.

This Tyvek wristband guide addresses the most common questions buyers face, examines wristband longevity under real-world conditions, helps you avoid costly mistakes with lead times, and shows you how to match the right wristband type to your specific event needs.

You’ll learn the distinction between waterproof and water resistance, and discover which branding and security features justify an investment in custom printing.

What material is used to make Tyvek wristbands? Tyvek wristbands are made from nonwoven high-density polyethylene (HDPE) fibres flash-spun and heat-bonded under pressure, providing tear resistance and water resistance for reliable one-day access control.

The typical GSM (grams per square metre) for event wristbands ranges from 43 to 55, striking an ideal balance between durability and comfort. The proprietary process creates continuous filaments that bond together without weaving or knitting. The resulting material is simultaneously paper-light and surprisingly strong.

When you try to rip Tyvek, stress disperses across its bonded filaments rather than travelling down a single tear line as it does in paper. This same structure, combined with HDPE’s non-absorbent nature, gives Tyvek its water resistance, helping the wristbands withstand sweat, rain and brief water exposure without breaking down. Even so, Tyvek isn’t indestructible.

UV degradation occurs over extended outdoor exposure, so while it’s fine for one- or two-day events, prolonged exposure to sunlight weakens fibre bonds and causes fading of printed designs.

Chemical interactions with certain solvents, oils, and alcohol-based hand sanitisers can compromise material or cause printed information to smudge. Edge wear develops at stress points, particularly where the adhesive closure meets the band. It’s the most common failure mode after 24-48 hours of active wear.

Buyers can identify low-quality Tyvek by checking for inconsistent thickness, weak tear resistance, and poor adhesive performance that allows easy removal without visible damage.

Tyvek bridges these extremes, delivering dependable single-day performance at a fraction of vinyl’s cost whilst dramatically outperforming paper.

Are Tyvek wristbands fully waterproof? Tyvek wristbands are not fully waterproof but are highly water-resistant, meaning they repel moisture effectively but will eventually fail under prolonged submersion or extreme humidity and friction. For aquatic events, vinyl or silicone wristbands become the appropriate choice.

However, the adhesive closure is the vulnerable point, and prolonged moisture exposure softens the bond, making the closure more prone to peeling, particularly if guests repeatedly manipulate the band.

Tyvek wristbands typically last 24-48 hours in normal event conditions, including moderate sweat exposure and humidity. After that, the adhesive begins to weaken, and edge wear becomes noticeable.

What factors shorten their lifespan at events? Several factors shorten the lifespan of Tyvek wristbands, including excessive friction with clothing, repeated wetting and drying cycles, direct UV exposure, contact with oils or chemicals, and guest tampering.

To give the bands the best chance of a long life, apply them snugly but not tightly, position them slightly higher on the forearm to reduce friction, and advise guests to avoid applying lotions or sanitiser directly to the band.

When is a plain Tyvek wristband sufficient? Plain Tyvek wristbands are sufficient when events require simple admission control without tiered access, branding is unimportant, and lead time is short or non-existent. School events, community gatherings, emergency credentials, and last-minute functions suit plain bands perfectly.

Custom Tyvek wristbands deliver branding opportunities, enhanced security through sequential numbering or barcodes, professional presentation, and data-capture capabilities that plain bands cannot match. Event logos, sponsor acknowledgements, safety messages, or social media hashtags transform wristbands into marketing assets.

Sequential numbering enables accurate attendance tracking and prevents duplicate entry. Barcodes or QR codes integrate with ticketing systems, enabling sophisticated zone management and real-time capacity monitoring.

Custom Tyvek wristbands typically cost 40-80% more than plain bands due to setup fees, design work, and longer production runs. Setup fees for artwork preparation and printing plate production are amortised across the order quantity, making larger orders proportionally cheaper per unit.

Minimum order quantities for custom bands usually start at 500-1000 units, while plain stock items can be purchased in any quantity. Lead times can range from immediate availability (plain) to 7-14 business days for standard custom orders.

Customised wristbands are recommended for corporate functions, ticketed festivals, branded activations, multi-day conferences, and events where sponsor visibility is crucial. Guests paying over $50 for a ticket will also expect a more professional presentation.

| Feature | Plain Tyvek Wristbands | Custom Tyvek Wristbands |

|---|---|---|

| Best For | Small events, school fetes, community gatherings, emergencies, and last-minute needs | Corporate functions, festivals, ticketed events, brand activations, multi-day conferences |

| Design & Branding | Solid colours only, no logos or print | Full-colour printing, logos, branding, barcodes, QR codes, numbering |

| Lead Time | In stock - ships same day or next business day with free standard shipping | Printed in-house, dispatched the same day your order is placed (if placed before 3 pm ACDT) |

| Minimum Order Quantity | 8 unit minimum - with cost per unit savings for bulk orders | 8 unit minimum - with cost per unit savings for bulk orders |

| Cost per Unit* | Low - approx. $0.08–$0.15 (see Plain Tyvek Wristband page for details) | Moderate - approx. $0.25-$0.80 + setup fees ($80-$200) (see Custom Tyvek Wristband page for details) Note: The Wristband Co. does not charge setup fees |

| Security Features | Sequential numbering, basic tamper-evident adhesive | Sequential numbering, barcodes, or QR codes for access control |

| Event Duration | Ideal for up to three-day use | Suitable for up to three-day use, but with added branded appeal |

| Advantages | Fast, affordable, easy to distribute | Strong brand visibility, better security, and professional presentation |

| Limitations | No branding, lower perceived value | Higher cost per unit |

Tyvek wristbands demonstrate impressive durability under typical event conditions, with tear strength exceeding 20 pounds and peel resistance sufficient to prevent casual removal whilst signalling tampering through visible damage.

What are the most common failure modes? The most common failure modes are edge curling at stress points, adhesive peel at the closure, and surface delamination from chemical exposure rather than material tearing.

Environmental factors that reduce Tyvek’s effectiveness include:

UV degradation becomes noticeable after 8-12 hours of direct sunlight, while chemical exposure from sunscreen, insect repellent, or sanitisers can dissolve adhesive or cause printed text to smudge.

Proper staff training, optimal tension, and guest education ensure wristband longevity. Bands should fit snugly, allowing two fingers underneath, preventing transfer without excessive tension.

Tyvek wristbands transform from simple admission tools into sophisticated access control devices.

Sequential numbering enhances event security by assigning unique identifiers to each band. With the distinct number, organisers can log issued numbers against ticket purchases, immediately identifying counterfeit bands. Sequential numbering deters “pass-back” fraud, where guests remove bands and hand them to friends outside.

Can Tyvek wristbands integrate with ticketing systems? Tyvek wristbands integrate effectively with ticketing systems through printed barcodes or QR codes that link each band to ticket database records, enabling automated validation and access control.

Standard barcode scanners or smartphone apps read codes, query the ticketing database, and confirm validity within seconds.

Organisers should choose advanced security features when ticket values exceed $100, fraud risk is substantial, or sponsors require counterfeit protection for premium access areas. Community gatherings and school events shouldn’t burden budgets with unnecessary security features.

At The Wristband Co., the cost of Tyvek wristbands is determined by four components: base materials, production, labour, and shipping.

Plain Tyvek bands cost $0.08-0.15 per unit in bulk quantities with a minimum order of 8 wristbands, whilst custom bands range from $0.25-0.80 per unit depending on order size, colours and features.

Plain Tyvek wristbands are always in stock and ship the same day or next business day, with free standard shipping included. Custom Tyvek wristbands are printed in-house and can be dispatched the same day an order is placed (provided artwork is approved and the order submitted before 3 pm ACDT). Both plain and custom Tyvek wristbands share the same minimum order quantity of 8 units, with faster or expedited delivery options available at checkout for customers who need their wristbands quicker.

Organisers can save money by ordering larger quantities to capture volume discounts, simplifying designs to reduce the number of colours and setup complexity, planning far ahead to avoid rush fees, and maintaining relationships with suppliers to secure continuation-order savings.

Ordering 20-30% more bands than minimum attendance estimates prevents expensive emergency reorders.

Tyvek wristbands from The Wristband Co. are supplied exclusively in perforated sheets, designed for easy tearing and fast distribution at events.

Custom Tyvek Wristbands and all 25mm Tyvek wristbands are provided in sheets of 8, whilst 19mm plain Tyvek Wristbands come in sheets of 10.

This sheet-based format ensures quick application, efficient storage, and simple organisation for event staff. Batch labelling clearly identifies quantities, colours, and any design variations, making it easy to allocate wristbands across multiple entry points or manage tiered access levels.

Organisers should stage wristbands before events by completing a pre-event checklist.

Buffer stock for large orders covers errors, damage, attendance fluctuations, and lost inventory. Plan 5-10% for under 1000 units, and 3-5% for larger orders due to more predictable variance.

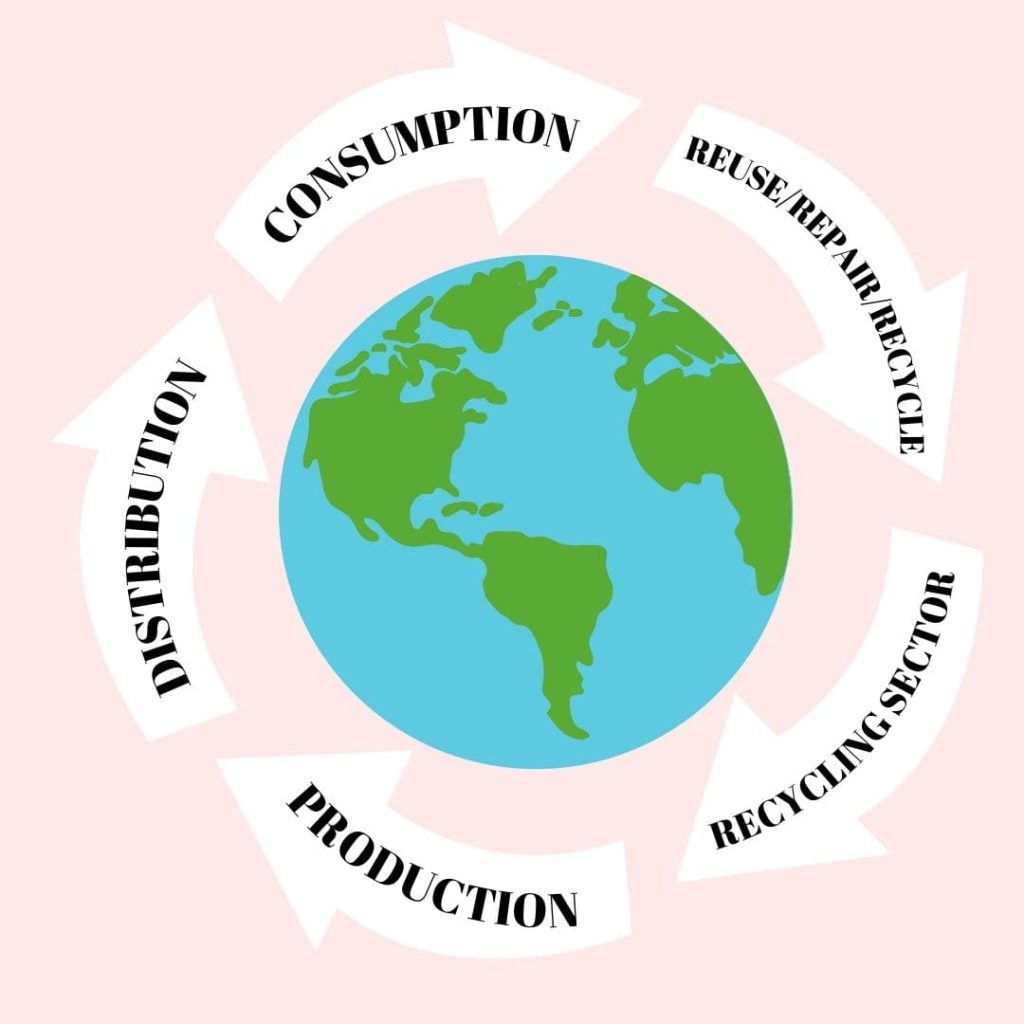

Why does Australian-made production lower environmental impact? Australian-made production dramatically reduces shipping distances and associated carbon emissions compared to offshore manufacturing.

Suppliers that use water-based or UV-curable inks, implement waste-reduction programs, and use recycled packaging demonstrate environmental commitment. Local production further reduces environmental impact by reducing freight and packaging and by adhering to stricter local standards.

Buyers should look for suppliers that demonstrate transparent sourcing practices, waste-reduction programmes, responsible ink and adhesive choices, recyclable or minimal packaging, and legitimate environmental certifications rather than vague “eco-friendly” marketing claims.

What future innovations may change the sustainability of Tyvek? Future Tyvek sustainability innovations may include fully recyclable variants, biodegradable adhesives, and hybrid smart wristbands using renewable materials.

Making the right wristband choice requires evaluating event requirements, budget constraints, security needs, and supplier capabilities through a structured decision framework.

What should every buyer ask before ordering Tyvek wristbands? Every buyer should ask:

Plain Tyvek wristbands are a great fit for events where straightforward admission control is all that’s required, offering a fast, affordable and reliable solution across a wide range of settings, from community gatherings to school functions and casual celebrations.

Custom Tyvek wristbands become valuable when an event benefits from added branding, clearer visual identification, or enhanced security features. They elevate the professionalism of an event, support sponsorship visibility and streamlines access control for organisers who want a more bespoke experience.

That being said, both options offer the same durability, multi-day flexibility, and ease of use; the choice largely depends on whether you want a practical identification tool or a branded, feature-rich wristband that adds extra polish and functionality.

Common mistakes buyers make when selecting wristbands include:

Organisers can vet suppliers and avoid many of these common mistakes by:

Tyvek wristbands lead the event market due to their durability, water resistance, tamper-evidence, and affordability.

Ensure your next event runs smoothly with durable, Australian-made Tyvek wristbands from The Wristband Co. Email our sales team [email protected] or phone 08 8363 4850 for tailored advice, accurate quotes, and fast turnaround on both plain and custom options.

Join our mailing list to receive product information, endless inspiration and 10% off your next order!

Monday – Friday 8:30 AM-8:30 PM

Saturday 10:00 AM-5:00 PM

Sunday CLOSED

38 Little Rundle Street Kent Town SA 5067

08 8363 4850

ABN: 62 239 772 879

The Wristband Co. is located on the traditional lands for the Kaurna people, and we respect their spiritual relationship with their Country. We also acknowledge the Kaurna people as the custodians of the Adelaide region and that their cultural and heritage beliefs are still as important to the living Kaurna people today.

Payments Accepted